The ratio of longitudinal stress to longitudinal strain is called Young’s modulus of elasticity in elasticity limit. It is represented by Y.

Young’s modulus of elasticity

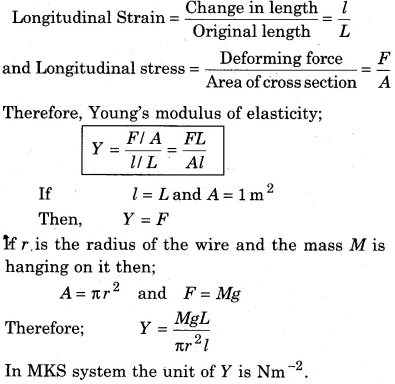

If on any wire of longitudinal cross sectional area A a tensile force F is applied then its initial length L and change in length is l, then;

The value of Y is calculated only for solids and it is a characteristic of solids.

When on every point of the surface of any object a perpendicular and equal force i. e., pressure is applied then the volume of the object changes but the nature or form does not change. This type of strain can be in all the three types of states of any material such as solid, liquid and gas. The change in the unit volume of the object is called ‘volume strain’ and the normal force (pressure) applied on unit area of the object is called ‘normal stress’. In the limit of elasticity the ratio of normal stress to volume strain is called bulk modulus of elasticity. It is represented by K.

If the material having surface area A; an equal normal deforming force F is applied on all the surfaces of the material; then due to this there is no change in the shape of the material but there is AV change in the original volume V then;

Negative sign shows that if pressure is increased then volume decreases and when pressure is decreased then volume increases i. e., the signs of P and ∆V are opposite.

Inverse of bulk modulus of elasticity is called compressibility. Therefore;

Hence, by quantitative form within the limit of elasticity the perpendicular and uniform applied force on any unit transverse cross sectional area; by which the volume of the object reduces to half of its initial volume; is equal to the bulk modulus of elasticity of that material.

For solids the value of bulk modulus of elasticity is very high than liquids and for liquids the value is much higher than gases. In this way solids are less compressible and gases are more compressible.

It is defined as the ratio of tangential stress to the shearing strain; within the elastic limit. It is represented by η.

From table we understand that the value of modulus of rigidity (η) is less than Young’s modulus of elasticity (Y) i.e., stretching or compressing an object (material) is more tough than deforming its shape.

For metals, Young’s modulus of elasticity is more. Therefore, to generate small difference in length of these materials; more force is required. Steel is more elastic than copper, brass and aluminium. Due to this reason the machines used for heavy works and structural designs give more preference to steel.

Set Before Numerical Examples

Factors Affecting Elasticity

The elasticity of a material is affected by the following factors :

(i) Effect of annealing : Annealing means heating and then cooling gradually. The process of annealing results into the formation of larger crystal gains. Here, the elasticity of the material decreases.

(ii) Effect of the impurities present in the material : The elasticity of the material can be increased or decreased by adding impurities in it depending on the nature of impurities.

(iii) Effect of hammering and rolling : Hammering and rolling leads to breaks up the crystal grains into the smaller peices. Thus the elasticity of the materials is increased.

(iv) Effect of temperature : The elasticity of the materials decrease with increase in temperature.

In Searle’s experiment there is a rectangular frame of metal. As shown in figure on a rigid base two wires A and B of same material have hook P and Q hanged. One end of the spirit level is attached to the frame P and second end is at the screw of the spherometer. The spherometer screw can be rotated up and down along a vertical pitch and along with it rotates the spirit level. The hanged weight W from hook P is a stable weight which does produce twist in the wire. The hook from Q has a hanger.

When any weight is placed on the string (wire) A then its length increases and the independent end of spirit level moves downwards. By rotating the spherometer the spirit level is brought in the horizontal position. By reading the initial reading and the final reading the distance travelled by the spherometer is calculated. This distance is the increased length due to weight.

Fig: Searle's apparatus to find out elastic constant

For different weights by experiment the increase in length is calculated. A graph is drawn by taking weight (M) on X-axis and increase (l) on Y-axis.

Suppose, the initial length of the wire A is L and applied mass is M, r is the radius of the wire and increase in length is l then;

screw gauge and value of L from metre scale can be calculated and kept in the formula and the value of Young’s modulus of elasticity is calculated.

The weight applied should not be more than the limit of elasticity. The limit of elasticity is dependent on the material and its radius.